We've covered everything from the basics of custom mechanical keyboards to building one from scratch. After building your own mechanical keyboard, modifying it to perfection is the next step in evolution. We've taken care of that with the Stabilizer and Switch mod guide. This brings us to the last part of the series of keyboard modifications where we improve the case and the keyboard plate. Be sure to read these articles to understand the basic terminology and concepts used in this guide.

SummaryKeyboards are percussion instrumentsWhat you need to get startedSound plate dampeningDon't forget the caseAs with stabilizers and switches, buying high-quality CNC-milled aluminum or brass housings won't set you back. Keyboard cases are hollow for the most part, but combine that with the snap of the keys, and you have a percussion instrument on your hands. No wonder fans of custom mechanical keyboards are pretty particular about their sound.

This is all the more important for expensive keyboards with CNC milled metal housings. These tend to have a higher pitch due to the nature of the material, causing them to sound thin and hollow without proper acoustic treatment. This guide aims to take care of that, i.e. acoustically dampen the case as well as the plate to improve the sound of your keyboard.

Much of a keyboard's hollow, metallic note comes from the metal plate vibrating with keystrokes. This is further amplified by the 3.5mm gap between the PCB and the plate acting as an acoustic chamber. We will fill this gap with a damping material to dampen the hollow sound. The anti-vibration properties of the material also prevent the plate from generating noise. This should allow the natural sound of the switch to stand out without being overshadowed by the noise of the plate.

1. It may seem counterintuitive, but we start by measuring the dimensions of the case instead of the plate. This applies to all types of case mounting styles, from tray mount to sandwich mount, as our goal is to have the sound dampening material (EVA foam in this case) to extend past the plate in order to create an airtight seal with the case. This will significantly reduce internal noise from leaks outside the case.

The foam conforms, so you can either use exact dimensions if using precise measuring instruments, or add a millimeter to each dimension. It is better to have more material and cut later than not to succeed.

2. Transfer the measurements to the EVA foam sheet.

The gap between the plate and the foam is 3.5 mm on all keyboards. EVA foam is usually found in sizes of 1mm, 2mm, 3mm and 5mm. You will therefore need to use two 2mm sheets or a combination of 3mm and 1mm sheets. The additional thickness of 0.5 mm improves damping. Use double-sided tape or foam-compatible glue to hold the sheets together. This is important to avoid headaches when cutting the sheet.

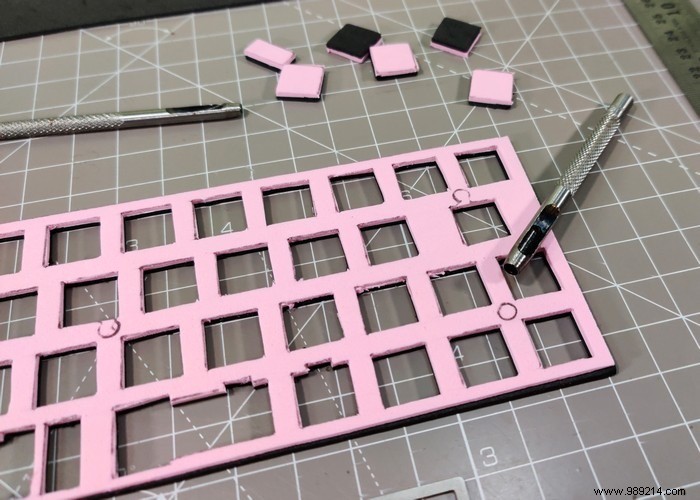

3. Use the plate as a stencil to transfer the cut lines to the EVA foam. Your cuts will be more accurate if you use a fine scoring tool and keep the cut lines closer to the edges of the plate.

4. Use a sharp cutter to make all cuts. Finer cuts, such as holes for switches, will be clean and precise if you use a sharp blade. Using a dull blade will make your job longer, frustrating and inaccurate.

Tray mount keyboards will need an appropriately sized hole punch to create space for the tray mount screw rods. You can also dig holes using a blade, but the result is neither as clean nor as precise as with a dedicated punching tool.

5. Depending on the physical dimensions of your preferred stabilizer type, you may or may not need to cut some materials to accommodate them.

6. Complete the PCB/plate assembly by soldering the switches to the PCB. Refer to our switch replacement guide on how to solder switches.

The acoustic treatment of the case is much less complicated and tedious compared to the plate. Lining the inside of a box with foam isn't complicated, but it's pretty important. The CNC-milled metal enclosures are very dense carriers that transfer internal noise quite effectively. Adding a layer of soundproofing prevents this from happening. The actual method will vary very slightly with your case mounting style. Be sure to read our guide to keyboard basics if that sounds Greek and Latin to you. This article covers all the basics.

1. The first step is to determine the clearance between the case floor and the PCB to determine the thickness of the EVA foam sheet. For tray mount cases, this involves measuring the height of the PCB mounting posts and deducting the height of the tallest component that protrudes from the bottom of the PCB. In the example below, the PCB is mounted at a height of 3.2mm, and the tallest component below the PCB is over 1mm, so we can use 2mm foam.

Calculations are even easier for all other types of enclosure mounting styles. All you have to do is measure the distance from the bottom of the plate to the bottom of the case. Then subtract it along with the mandatory 3.5mm gap between the plate and the PCB plus the thickness of the PCB and the tallest component protruding from it. For example, if the distance between the bottom of the plate and the bottom of the case is 10mm, the PCB is 2mm thick, and the tallest component on the bottom side is 1.5mm high , you can use 10 – (3.5 + 2 + 1.5) =3 mm thick EVA foam sheet.

2. We have already measured the dimensions of the case, so all that remains is to cut the EVA foam inserts to the appropriate dimensions. Tray mount enclosures require drilled holes for mounting posts. Additional cutouts for the USB port should also be measured, marked and cut as shown below.

3. If your case has hollow sections, measure the depth and fill with an appropriately sized EVA foam cutout.

4. With the housing floor acoustically treated, we move on to the four vertical sides. Remember the distance from the bottom of the plate to the floor of the case you measured earlier? This is the width of the EVA foam strip you will need to cover the sides of the case. The thickness of this foam strip should be at least 1 mm for effective damping and should not exceed 2 mm, otherwise the PCB will cling to it.

Top/bottom mount, gasket mount and sandwich mount cases will require some gaps to be left in this band as shown below. The spaces are necessary to avoid clearance problems with the mounting posts.

That's all we can say about it. Assemble your keyboard and admire how radically improved it sounds.