If you're reading this, chances are you've been exposed to the world of custom mechanical keyboards through TechTubers or even mainstream tech media. You came here looking for one of your own, but you don't know where to start. This is not surprising since building a custom mechanical keyboard is a complicated niche and internet forums tend to be more confusing than helpful.

ContentsWhat Are Custom Mechanical Keyboards?Choosing the Right Form FactorCustom Keyboards Require Custom ComponentsKeys Are Surprisingly ComplicatedExplanation of Basic Switch TypesCase Types and Mounting StylesTop Mount KeyboardsIntegrated Plate KeyboardsTop, Bottom and Sandwich KeyboardsKeyboards gasket mountedIf only there was a practical, simplified guide good enough to get you started, something that lets you learn the ropes the best way to learn anything, and that is by getting dirty hands. Well, that's this guide.

Before we can get out the screwdriver and soldering iron, we need to get a few things in order. To get started, answer basic questions like what is a custom mechanical keyboard for and who is it even for? Mechanical keyboards are higher quality alternatives to cheap membrane keyboards found in laptops and desktop computers. The custom part of custom mechanical keyboards comes from two main aspects that are of most interest to keyboard enthusiasts:

The need for higher quality components should be obvious, but custom mechanical keyboards look, sound, and feel better than their mass-produced counterparts. These keyboards are aesthetically superior thanks to high-quality keycaps that are usually color-coordinated with custom sleeved cables and handmade acrylic or wood palm rests. Their appeal, however, extends beyond beauty. These keyboards offer a noticeably better typing feel thanks to exotic switches combined with custom cases milled from solid blocks of aircraft-grade aluminum.

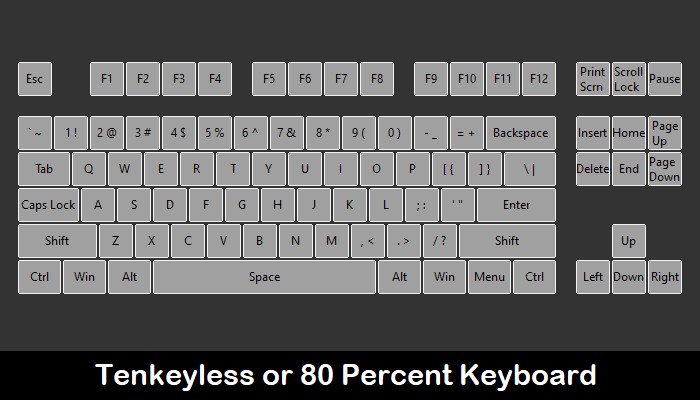

Each derivative keyboard form factor is created by omitting one or more of these elements, each named with respect to the percentage of the full-size keyboard. Tenkeyless (TKL) or 80% keyboards, for example, omit the numeric keypad altogether. This form factor is popular with gaming keyboards because it frees up space for a larger mouse pad without requiring gamers to overextend their arms.

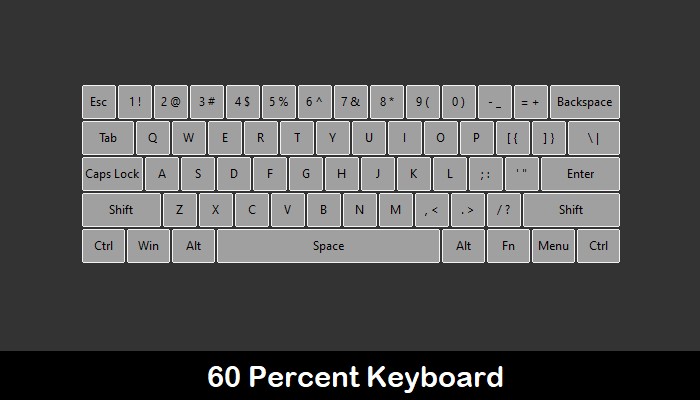

However, the 60% form factor is preferred in the custom mechanical keyboard scene due to its portability and the way it keeps virtually every key within easy reach. This is a useful feature for touch typists, who are loath to remove their hands from the main row. This form factor does away with everything but the alphanumerics and modifiers, with the function keys and arrow keys hidden behind a separate layer accessed using a dedicated function key.

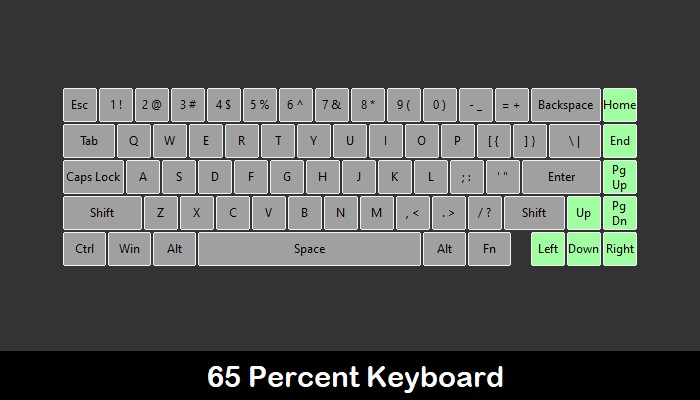

The 65% form factor is essentially a 60% keyboard with a single column of often-used navigation keys along with the arrow cluster adapting to the existing layout while extending the keyboard by a single column. It's a popular choice among keyboard geeks who can't live without arrow keys.

Then there are crazier form factors such as the diminutive 40 percent keyboard, which is basically a 60 percent keyboard missing the entire row of numbers and a few modifiers as well. This form factor is also popular with touch typists who claim to be as fast on these keyboards (if not faster) than even full-size keyboards.

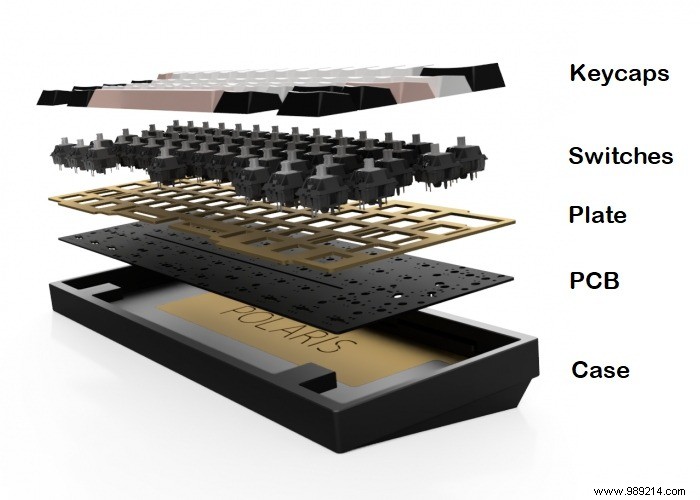

By now you will have an idea of the keyboard form factor you prefer. But you still can't build a keyboard without knowing what's inside. Most keyboards are made up of six main parts. The visible components of the keyboard include the keys and the enclosure, which is the chassis that houses all of the other components and gives the keyboard its familiar silhouette.

Keys are attached to switches, which typically use a mechanism that takes advantage of electrical contacts to register input. These are in turn soldered onto a PCB. It's the brain of the keyboard, and it's littered with conductive traces that connect all the switches to the microcontroller.

Next comes the plate. This is the skeletal support frame that holds the switches firmly in place and prevents the soldered joints from being stressed. Finally, stabilizers are either attached to the plate or the PCB, and these help stabilize long keys such as spacebar, enter, and shift. Without stabilizers, these keys would simply flip around the switches.

Knowing the components of a keyboard is one thing, but choosing the right type takes greater insight. Let's take a look at what separates the different varieties of components.

The keys have the biggest influence on the appearance of the keyboard, followed by the sound itself. While you can pick up a good set of keycaps for $30, it's not uncommon for keyboard enthusiasts to spend up to $200 on some high-quality sets. Keycap sets are available in a variety of profiles such as OEM, Cherry, SA, DSA and MT3. These differ in shape and height, as well as affecting the look, feel and sound of the keyboard.

The cheapest keycaps are made of ABS plastic and have laser-etched or pad-printed legends. This type of plastic wears out faster and develops an unsightly shine over time. The print is also less durable. The opposite end of the spectrum is populated by PBT plastic keycaps, with legends formed using a complicated and expensive double-injection process or heat-sublimation. PBT plastics are resistant to wear as well as shine. Legends formed by the heat sublimation or double injection process are virtually impossible to erase.

Switches fall into three main categories:clickable, tactile, and linear. Clicky switches produce both tactile feedback and an audible click when the switch is operated. They are ideal for typists. Tactile switches, on the other hand, only provide a pronounced tactile bump instead of a click when actuated. These switches are for typists who want feedback while typing but prefer a relatively quieter keyboard.

Linear switches do not provide tactile or clicky feedback when the switch is pressed. These switches are typically chosen by gamers who want fast, consistent actuation conducive to repetitive presses of gaming-compatible keys. Each category of these switches can be further customized with varying spring weights and quiet variants.

Choosing a favorite switch from hundreds of different options is a deeply subjective and personal experience. It's a journey of self-discovery that you have to go through on your own.

The case is the most important factor affecting the build quality as well as the sound of the keyboard. The cheapest cases are made from injection molded plastic and generally have poor structural rigidity and fit/finish levels. However, CNC machined cases made from quality plastics, such as polycarbonate and frosted acrylic, are not uncommon either. The higher end cases are machined from solid blocks of aluminum and reinforced with brass weights. These are widely considered the gold standard in the custom keyboard space.

Notwithstanding the choice of case material, the cost and complexity of any custom keyboard is further dictated by the mounting style. As the name suggests, the mounting style of a keyboard decides how the plate (or in some cases the PCB) is mounted to the chassis.

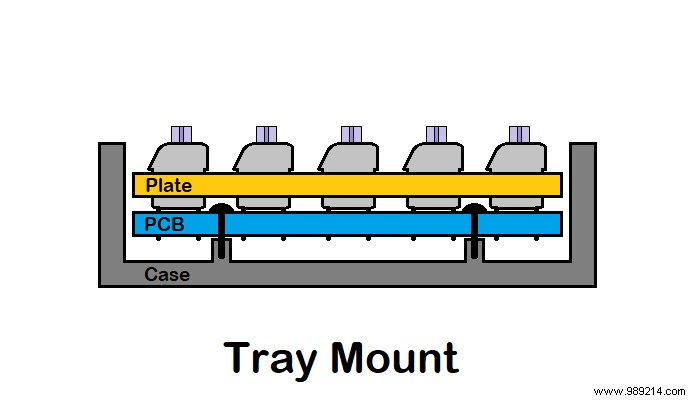

Tray-mounted keyboards tend to be the cheapest and easiest to make. Unsurprisingly, this style of mounting is the staple in nearly every entry-level custom mechanical keyboard. Tray mount keyboards have the PCB screwed to mounting posts that protrude from the case. However, this leads to inconsistent sound because the PCB is stiff near the mounting posts and flexible farther from them. This effect can be controlled by opting for a more rigid aluminum or brass plate but cannot be completely eliminated.

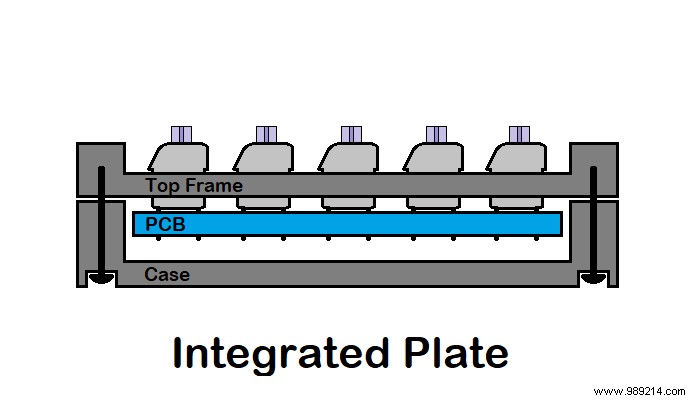

The integrated plate design is the opposite of this approach and uses a two-piece case, where the top half serves as both the plate and the top frame of the case. This design is relatively more expensive to manufacture but provides consistent sound, albeit at the cost of completely eliminating flex, which leads to a harsher experience when lowering switches.

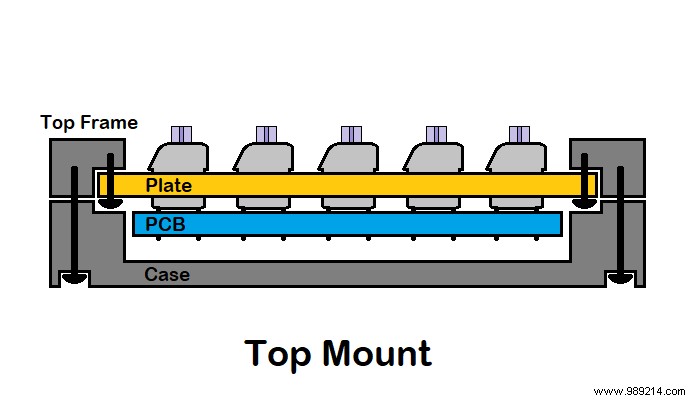

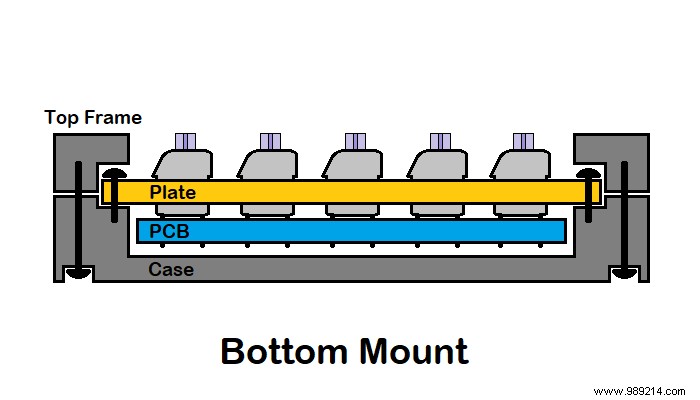

The third major type of keyboard assembly is even more complex and expensive to implement, as it requires a two-part chassis in addition to a dedicated plate. This includes top-mount, bottom-mount, and sandwich-mount keyboards, with each type indicated by the part of the chassis the plate attaches to. This style of keyboard construction provides a consistent sound. In addition, as the plate is attached to the chassis along the edges, it also opens up the possibility of using flexible materials such as polycarbonate for those who prefer a softer bottom.

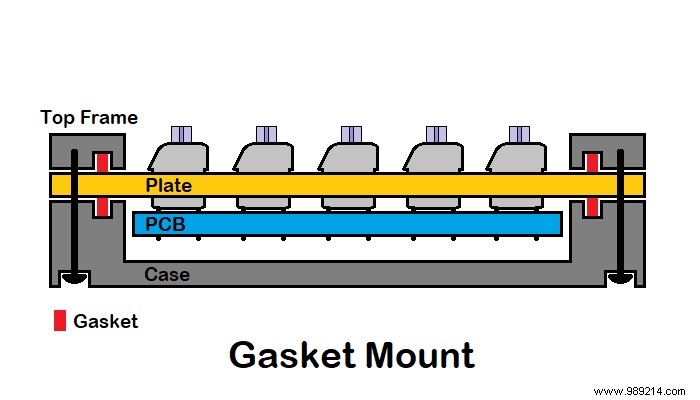

Some new custom mechanical keyboards (not to mention expensive ones) now come with silicone gaskets sandwiched between the plate and the chassis in various combinations of the aforementioned mounting styles. The basic idea is to further isolate the switches from the chassis for a better sound signature and better tactile feedback. These are collectively referred to as Gasket Mount Keyboards.

That's basically all you need to know to take the next step in creating your own custom mechanical keyboard, which is choosing the right parts based on your personal preferences. The next and final installment of this guide will show you where to find the components and how to assemble them.

Related :Choosing a mechanical keyboard - Which type of mechanical keyboard switch is best for me?