The size of a processor's process node is always something that is frequently discussed in chip specs. But what is it and why is it important?

SummaryWhat does "process size" mean? Why is smaller better? What is the downside of smaller process size? Conclusion

If you shrink all parts of a transistor equally, the electrical properties of that transistor will not change. And the more transistors you can fit in a given space, the more processing power you'll have. This is thanks to increased computational parallelism and cache sizes. So if you're trying to speed up a chip or add new features, there's a strong incentive to downsize its transistors.

Smaller processes also have lower capacitance, allowing transistors to turn on and off faster while using less power. And if you're trying to make a better chip, that's fine. The faster a transistor can turn on and off, the faster it can operate. And transistors that turn on and off with less power are more efficient, reducing the operating power, or "dynamic power consumption," required by a processor. A chip with lower dynamic power consumption will drain batteries slower, cost less to operate, and be more environmentally friendly.

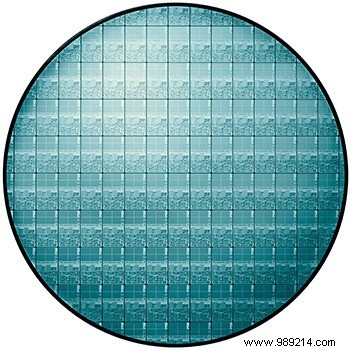

Smaller chips are also cheaper to manufacture. The chips are fabricated on circular silicon wafers, like the one above. A single wafer will typically contain dozens of processor dies. A smaller process size will create a smaller matrix size. And if the die size is smaller, more dies will fit on a single silicon wafer. This leads to an increase in manufacturing efficiency, reducing manufacturing costs. The development of a new process requires a major investment, but once this cost is recovered, the costs per die drop considerably.

Smaller transistors are more difficult to manufacture. As transistors shrink, it becomes increasingly difficult to manufacture chips that operate at the highest possible clock speed. Some chips will not be able to run at maximum speed, and these chips will be "ranked" or labeled, as chips with lower clock speeds or smaller caches. Smaller processes usually have more chips stored at lower clock speeds because creating a "perfect" chip is more difficult. Manufacturers are careful to eliminate as many problems as possible, but it often comes down to the inevitable variations of the analog world.

Smaller transistors also have greater "leakage". Leakage is a measure of how much current a transistor lets through when it is in the "off" position. This means that as the leakage increases, the static power consumption or the amount of power consumed by a transistor at rest also increases. A chip with greater leakage requires more power even when not active, draining batteries faster and operating less efficiently.

A smaller process may have lower throughput, resulting in fewer fully functional chips. This can lead to production delays and shortages. It is therefore more difficult to recover the investment necessary to develop a new process. This element of risk underlies any new manufacturing process, but it is especially true for a process as precise as semiconductor manufacturing.

Of course, manufacturers try to reduce or eliminate these problems when developing a new process, and they often succeed. That's why we get faster and more efficient chips even when the process size decreases.

Reducing process size is difficult, but the benefits are a strong incentive for manufacturers to seek ever-smaller process sizes. And thanks to this drive, consumers get faster, more efficient chips every two years. It is these advances that have made technological marvels like smartphones possible, and that will enable the next generation of technological achievement.